As EV charging modules and high-power converters continue to increase in output density, engineers in the thermal industry are facing greater challenges in removing concentrated heat efficiently. Many teams now look toward advanced fin-forming technologies to stabilize thermal performance without adding unnecessary bulk. In this context, skived heatsink designs are frequently evaluated for their ability to maintain stable operation across fluctuating loads. Manufacturers like Dingmetal provide these solutions to support applications where reliability and continuous power flow are critical.

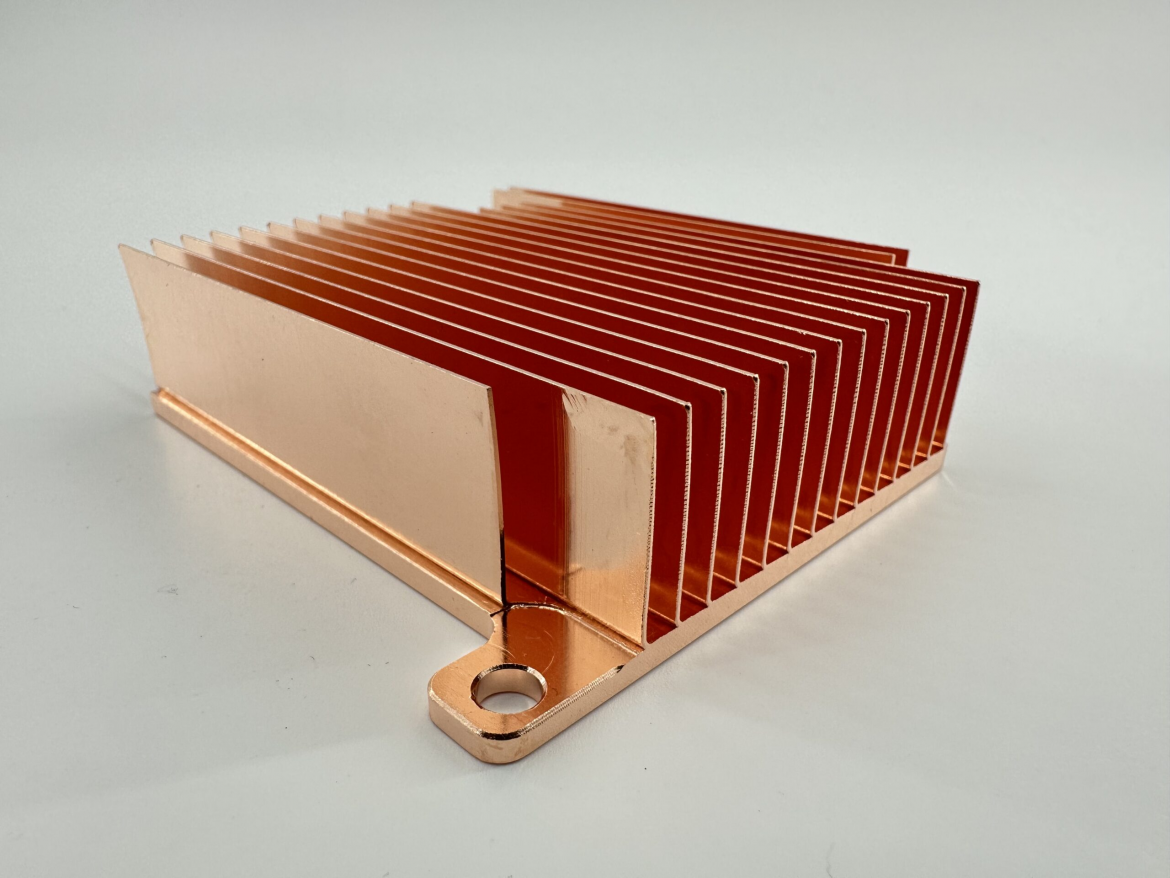

A skived heat sink is formed by slicing thin, closely packed fins directly from a single block of copper or aluminum. Because the fins and base remain a unified piece, there is no solder layer or mechanical interface that could trap heat. This one-piece structure enhances consistency and lowers thermal resistance, which is highly valuable for EV systems requiring rapid dissipation. For charging modules with compact enclosures, the high fin density created by precision skiving helps maximize available surface area without changing the footprint of the device.

How Skived Construction Supports EV Charging Modules

EV charging modules experience rapid temperature changes due to dynamic charging profiles, high current loads, and varying environmental conditions. These variations can affect lifespan, efficiency, and electrical safety. Many engineers evaluate skived heatsink solutions because the uniform fin thickness and tight spacing promote controlled airflow behavior, allowing heat to be removed evenly across the entire structure. When utilized in charging cabinets or liquid-assisted cooling modules, the geometry of skived heat sinks also improves contact between the coolant and fin surfaces.

They, such as Dingmetal, develop skived units with a focus on precise metal cutting, material integrity, and predictable performance under thermal cycling. Because no secondary assembly is required, these heat sinks avoid warping or detachment issues that can appear in mechanically bonded fin structures. For power conversion systems that operate at sustained high loads, the stability of skived fins helps keep switching components—such as MOSFETs, IGBTs, or SiC modules—within safe temperature ranges.

Advantages for High-Power Converters and Integration Considerations

High-power converters must deliver consistent output while managing thermal spikes generated by fast switching and dense circuitry. Engineers often select skived heat sinks due to their high surface-to-volume ratio, which enables greater heat transfer without adding excessive mass. The mechanical strength of one-piece fins is also beneficial when converters are installed in environments with vibration or shock, including charging stations exposed to outdoor conditions.

They, including Dingmetal, typically support customization for converters that require specific base thickness, fin height, mounting hole patterns, or integration with vapor chambers and heat pipes. Such adaptability is important for R&D teams building compact modules where thermal plates and power components must align precisely. Because the skiving technique is flexible across copper and aluminum, teams can choose materials based on conductivity requirements and cost expectations while maintaining structural uniformity.

Conclusion:Reliable Thermal Methods for Evolving Power Electronics

In EV charging modules and high-power converters, managing heat effectively is essential for stable performance and longer component life. Skived heat sinks offer a practical balance of efficiency, surface area, and mechanical strength through their unified metal construction. With precise fin geometry and consistent material quality, skived heatsink designs remain a dependable choice for engineers addressing the challenges of high-density power applications. Companies like Dingmetal continue to supply adaptable solutions that support these demanding environments, helping R&D and procurement teams implement dependable thermal strategies.